Abstract

Large-scale optoelectronics integration is limited by the inability of Si to emit light efficiently1, because Si and the chemically well-matched Ge are indirect-bandgap semiconductors. To overcome this drawback, several routes have been pursued, such as the all-optical Si Raman laser2 and the heterogeneous integration of direct-bandgap III–V lasers on Si3,4,5,6,7. Here, we report lasing in a direct-bandgap group IV system created by alloying Ge with Sn8 without mechanically introducing strain9,10. Strong enhancement of photoluminescence emerging from the direct transition with decreasing temperature is the signature of a fundamental direct-bandgap semiconductor. For T ≤ 90 K, the observation of a threshold in emitted intensity with increasing incident optical power, together with strong linewidth narrowing and a consistent longitudinal cavity mode pattern, highlight unambiguous laser action11. Direct-bandgap group IV materials may thus represent a pathway towards the monolithic integration of Si-photonic circuitry and complementary metal–oxide–semiconductor (CMOS) technology.

Similar content being viewed by others

Main

Although a group IV direct-bandgap material has not been demonstrated as yet, Si photonics using CMOS-compatible processes has made great progress through the development of Si-based waveguides12, photodetectors13 and modulators14. The technology now emerging is rapidly expanding the landscape of photonics applications towards tele- and data communications, as well as sensing from the infrared to the mid-infrared wavelength range15,16,17. The light sources for such systems are currently lasers made from direct-bandgap group III–V materials operated off- or on-chip, and therefore require fibre coupling or heterogeneous integration, for example by wafer bonding3, contact printing4,5 or direct growth6,7. Hence, a laser source made of a direct-bandgap group IV material would further boost lab-on-a-chip and trace gas sensing15, as well as optical interconnects18, by enabling monolithic integration. In this context, Ge has a prominent role because its conduction band minimum at the Г-point of the Brillouin zone (referred to as the Г-valley) is located only ∼140 meV above the fourfold degenerate indirect L-valley. To compensate for this energy difference and thus form a laser gain medium, heavy n-type doping of slightly tensile-strained Ge was proposed19. Later, laser action was reported for optically20 and electrically pumped Ge21 doped to ∼1 × 1019 cm−3 and 4 × 1019 cm−3, respectively. However, pump–probe measurements of similarly doped and strained material did not show evidence for net gain22 and, in spite of numerous attempts, researchers have failed to substantiate the above results. Other concepts that have been investigated concern the engineering of the Ge bandstructure towards a direct-bandgap semiconductor using micromechanically stressed Ge nanomembranes9 or Si3N4 stressor layers23. Very recently, Süess et al.10 presented a stressor-free technique that enables the introduction of more than 5.7% (ref. 24) uniaxial tensile strain in Ge µ-bridges via selective wet under-etching of a prestressed layer. An alternative technique to achieve a direct-bandgap material is to incorporate Sn atoms into a Ge lattice, which primarily reduces the gap at the Г-point. With a sufficiently high fraction of Sn, the energy of the Г-valley decreases to below that of the L-valley. This indirect-to-direct transition for relaxed GeSn binaries has been predicted to occur at ∼20% Sn by Jenkins and colleagues25, but more recent calculations indicate much lower Sn concentrations in the range of 6.5–11.0% (refs 26, 27). A major challenge for the realization of such GeSn alloys is the low (<1%) equilibrium solubility of Sn in Ge28 and the large lattice mismatch of ∼15% between Ge and α-Sn. For GeSn grown on Ge substrates, this mismatch induces biaxial compressive strain, causing a shift of the Г- and L-valley crossover towards higher Sn concentrations27. Hence, strategies have been adopted to obtain partially and also fully relaxed GeSn layers on Si29 and on lattice-matched InGaAs ternary alloy30, respectively. Here, we adopt the partial relaxation of up to 560-nm-thick layers of GeSn on Ge/Si(001)-virtual substrates (Ge-VS).

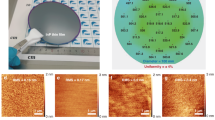

In the present study we investigated five samples (A to E) grown using an industry-compatible 200 mm wafer reduced-pressure CVD AIXTRON Tricent reactor and Ge2H6 and SnCl4 as precursors31,32. The GeSn layer thickness was 200–300 nm for samples A to D and 560 nm for sample E. The Sn concentrations (Table 1) were determined by Rutherford backscattering spectrometry (RBS) and X-ray diffraction reciprocal space mapping (XRD-RSM; Supplementary Fig. 1). The Ge buffer layers grown at 400/750 °C contained a weak biaxial tensile strain of 0.16% at room temperature due to the different thermal expansion coefficients of Si and Ge. The strain levels as well as Sn concentrations in the partially relaxed GeSn layers are summarized in Table 1. The latter were determined from a modified version of Vegard's law33. The experimentally determined Sn concentration and strain were used to calculate the electronic bandgaps at room temperature (Supplementary Fig. 2). Sample A, containing ∼8% Sn, was expected to be an indirect-bandgap semiconductor, because its L-valley is well below its Г-valley in energy. In samples B and C, the difference between the Г- and L-valleys (c.f. Table 1) was smaller than kBT at room temperature. According to the calculation, the −0.71% strained sample D exhibits a fundamental direct bandgap with the Г-valley 28 meV below the indirect L-valley. Sample E is a replica of sample D, except for the epilayer thickness, which has been increased to improve the overlap between the optical mode and the gain material.

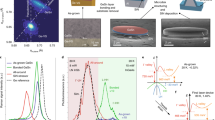

The cross-sectional transmission electron microscopy (XTEM) micrographs in Fig. 1a,b of sample D (12.6% Sn) show the high crystalline quality of the GeSn layer and reveal a high density of misfit dislocations at the interface (orange arrows). Part of the plastic relaxation occurred through the creation of dislocation half-loops (blue arrows) extending into the Ge buffer layer. High-resolution imaging (Fig. 1c) shows that most of the misfit dislocations at an average spacing of 12.5 nm are pure edge dislocations with a Burgers vector of a/2[110]. These so-called Lomer dislocations are the most efficient type of dislocation to induce strain relaxation34. The fact that no threading dislocation reached the sample surface in any of the examined TEM samples allows an estimate of the upper limit of the threading dislocation density of 5 × 106 cm−2.

a, Cross-sectional TEM image of Ge0.874Sn0.126 (sample D). b, Dislocation loops (indicated by blue arrows) emitted below the Ge0.874Sn0.126/Ge interface (indicated by orange arrows) penetrate only into the Ge buffer. c, High-resolution TEM image of the interface used for Burgers vector calculations. Lomer dislocations with b = a/2[110] are identified.

To prove whether the bandgap is fundamental direct or indirect, temperature-dependent photoluminescence measurements (see Methods) were performed. Figure 2a presents photoluminescence spectra in the range of 20–300 K for four different GeSn alloys (samples A–D). Note that the ordinate is fixed to facilitate the comparison of peak intensities. Going from sample A at room temperature to sample D at 20 K, the peak intensity increases approximately 350 times. This enormous gain in intensity is a combined consequence of sample cooling and inversion of the band offset between Г- and L-valleys. The weak, broad luminescence observed around 0.4 eV at lower temperatures might stem from misfit dislocations formed at the GeSn/Ge interface (discussed above). The photoluminescence intensity of the main peak is linearly related to the excitation power, which is characteristic for a dominant band-to-band recombination (Supplementary Fig. 3). Figure 2b presents the integrated photoluminescence intensity as a function of temperature. The curves are normalized to unity at 300 K. For 8% Sn (sample A), the Г-valley emission intensity strongly decreases with decreasing temperature, which is typical for Ge35 and low-Sn-content GeSn alloys36. The Г-valley luminescence of sample D steadily increases by about two orders of magnitude with the temperature decreasing from 300 K to 20 K. This change in behaviour is consistent with the fundamental bandgap being direct. The temperature dependence of the integrated photoluminescence intensities of samples B and C is more complex. For temperatures ≥150 K the intensities remain nearly constant, and they increase slightly for T ≤ 150 K. The explanation for this involves the application of a joint density of states (JDOS) model (Supplementary Section 4), including calculated effective masses and valence band parameters (Supplementary Tables 1 and 2). The energy difference ΔE between the Г- and L-valleys is used as a fitting parameter together with the optically injected carrier density nC(T) = (n0/τ0)τ(T), where n0 represents the density of carriers at room temperature, τ(T) is the temperature-dependent recombination time and τ0 = τ(300 K). For the fit we assume the following: (1) τ(T) is identical for all samples and (2) τ(T) resembles the Shockley–Read–Hall (SRH) recombination process (Supplementary Fig. 4). An excellent fit of the T-dependence of the photoluminescence intensity is presented in Fig. 2b. We also find that n0 = 4 × 1017cm−3, which agrees with the excitation density (see Methods) and a τ0 of 0.35 ns corresponding to a surface recombination velocity of 570 m s–1. Similar relaxation times have been measured for elemental Ge37, supporting the high crystalline quality of our GeSn layers. In the fit of sample D, the Г-valley lies 25 meV below the L-valley, in excellent agreement with the prediction of a fundamental direct bandgap. For sample A, the experiments reveal a clear indirect bandgap with an −80 meV offset compared to the prediction of ΔE = −50 meV. To extract the dependence of the conduction band offset on Sn concentration, xSn, the measured values were extrapolated to a strain of 0% using ΔE = 7.7 eV per unit strain following the model calculations. The direct bandgap as revealed by experiment is therefore reached for fully relaxed samples for Sn concentrations of ∼9%, which is in fair agreement with the theoretical prediction shown by the green line in Fig. 2c.

a, Temperature-dependent photoluminescence spectra for samples A to D. b, Integrated photoluminescence intensities normalized to the corresponding intensity at room temperature. Coloured curves show the result of a photoluminescence intensity simulation that includes the calculation of the joint density of states (JDOS), with the band offset ΔE between the minima of the Γ- and L-valleys being the key fitting parameter. c, ΔE as a function of Sn concentration. The indirect-to-direct bandgap transition is found at ∼9% Sn for unstrained layers using 7.7 eV per unit of strain for the extrapolation.

As we will show in the remainder of this Letter, sample E (which is the thicker pendant of layer D; Supplementary Fig. 5) provides sufficient optical gain to enable lasing. For the gain measurement, the luminescence was collected from the edge of a several-millimetre-long and 5-µm-wide waveguide structure that was excited over a variable length L by a 5-ns-long laser pulse at a wavelength of 1,064 nm.

Figure 3a presents photoluminescence spectra at 20 K with an optical excitation of 595 kW cm–2 for different stripe lengths, revealing a more than linear increase of the intensity and a substantial decrease in linewidth for increasing stripe lengths L (plotted in Fig. 3b). As expected, the photoluminescence emission energy of sample E (∼0.55 eV, which corresponds to a wavenumber of 4,435 cm−1 and wavelength of 2.25 µm) closely matches the one observed for sample D. The emission shifts to the blue with increasing excitation power (Fig. 3b). The inset to Fig. 3a indicates an overlap of the fundamental mode with the GeSn layer of ∼60% (c.f. Supplementary Table 3). The modal gain g, which includes waveguide losses, is determined for four different excitations from38 IASE = IO + ISP/g[exp(gL) – 1], as shown in the lower part of Fig. 3b, where IASE and ISP refer to the amplified and unamplified spontaneous emission, respectively. IO. contains contributions from the excited (but not amplified) higher-order modes as well as light collected from the sidewalls. We limited the gain analysis to excitations of <600 kW cm–2 and lengths of ≤550 µm to avoid the stimulated feedback of backwards-reflected light from the waveguide sidewalls. The obtained modal gain as a function of pump energy is plotted in Fig. 3c, and a differential gain of 0.40 ± 0.04 cm kW–1 is obtained from the slope. By extrapolation to the gain onset, we obtain a threshold excitation density of ∼325 kW cm–2.

a, Amplified spontaneous emission (ASE) spectra obtained from the 560 nm Ge0.874Sn0.126 layer (sample E) excited over lengths L between 50 and 400 µm at 595 kW cm–2. Inset: calculated intensity of the fundamental transverse electric mode (colour-coded) within a 5-µm-wide, 900 nm steep waveguide structure, revealing an overlap with the GeSn layer of 60%. b,c, Top (b): FWHM of the spectra presented in a, decreasing with increasing stripe length, L. Bottom (b): ASE intensities for the peak energies (551 meV and 558 meV), fit using IASE = IO + (ISP/g)[exp(gL) – 1] to determine the modal gain (plotted in c as a function of excitation). Red: modal gain, obtained from the lasing threshold observed in homogeneously excited Fabry–Perot waveguide cavities with lengths of 250 µm, 500 µm and 1 mm.

By exciting over the full length of a 1-mm-long waveguide and hence employing the multiple reflections feedback from the waveguide facets forming a Fabry–Perot cavity (Fig. 4c, inset), an unambiguous proof of lasing can be seen in Fig. 4a as a distinct threshold in output intensity. Once this threshold is exceeded, the full-width at half-maximum (FWHM) decreases and the emission intensity increases dramatically (Fig. 4b). The laser intensity increase flattens at ∼650 kW cm–2, which we attribute to sample heating. Shot-to-shot fluctuations of the excitation power are the reason for the lasing onset lying slightly below the gain onset, as found from the variable stripe length measurement. Similarly, the modal gain, as estimated from the reflection losses using α = 1/L·ln(1/R) with reflectivity R, appears at lower average excitation values according to Fig. 3c. At 1,000kW cm–2 peak excitation, lasing was observed up to 90 K (Fig. 4a, inset). This temperature coincides with the activation temperature for SRH recombination (Supplementary Fig. 4). Hence, we tentatively ascribe the threshold degradation as well as the still low external differential quantum efficiency (estimated at 1.5%; Supplementary Fig. 6) to a reduced carrier lifetime due to as yet unidentified extrinsic recombination centres together with the small energy separation between Г- and L-valleys, and valence interband absorption22. The operating temperature and lasing efficiency can be improved by introducing heterostructure layers comprising GeSnSi/GeSn31 for carrier confinement and by n-doping19.

a, Power-dependent photoluminescence spectra of a 5-µm-wide and 1-mm-long Fabry–Perot waveguide cavity fabricated from sample E (dGeSn = 560 nm, 12.6% Sn). Inset: temperature-dependent (20–100 K) photoluminescence spectra at 1,000 kW cm–2 excitation density. b, Integrated photoluminescence intensity as a function of optical excitation for waveguide lengths LC = 250 µm, 500 µm and 1 mm. Inset: FWHM around the lasing threshold for the 1-mm-long GeSn waveguide. c, High-resolution spectra of 250- and 500-µm-long waveguides taken at 500 kW cm–2. The mode spacings are 0.50 meV and 0.27 meV, which correspond to a group refractive index of ∼4.5 for the lasing mode. The pump laser homogeneously excites the waveguide cavity, and the light emitted from one of the etched facets is analysed (inset).

Figure 4c presents a final piece of evidence for lasing11 by showing the Fabry–Perot oscillations observed in 250- and 500-µm-long waveguide structures. From the oscillation period, a group mode refractive index of 4.5 is deduced, which reflects the dispersion of the refractive index in the pumped GeSn as well as in the Ge substrate37.

In summary, we present detailed photoluminescence studies performed on high-quality, partially strain-relaxed GeSn layers with Sn concentrations of up to 12.6% grown on Ge-buffered Si(001) substrates. Structural investigations show a low density of threading dislocations, homogeneously distributed Sn atoms, and mild compressive strain levels facilitated by a particularly favourable relaxation mechanism. The existence of a direct-bandgap group IV semiconductor that exhibits modal gain is demonstrated. Fabry–Perot resonators are fabricated, permitting the demonstration of lasing under optical pumping. Owing to the striking relation between the SRH recombinations and laser quenching at ∼90 K, surface passivation and design optimization regarding doping, optical mode confinement and carrier injection will help to increase the operation temperature as well as decrease the threshold excitation density. In a forthcoming development, electrical injection in optimized SiGeSn/GeSn/SiGeSn double heterostructures15,31 will be demonstrated. In conclusion, although lasing is achieved at low temperatures and relatively high optical pumping, this demonstration of a direct-bandgap group IV laser on Si(001) represents a promising proof of principle for a CMOS-compatible gain material platform for cost-effective integration of electronic and photonic circuits.

Methods

GeSn layers were grown on thick Ge/Si virtual substrates using a CVD AIXTRON Tricent reduced-pressure reactor. Growth temperatures were chosen between 350 and 390 °C, at rates between 17 and 49 nm min–1.

The bandstructure around the Г point was calculated by the 8-band k.p method including strain effects. Indirect conduction band valleys split with the applied strain, as described via appropriate deformation potentials. The parameters used are provided in Supplementary Table 1.

For photoluminescence spectroscopy, a continuous-wave solid-state laser emitting at a wavelength of 532 nm with a power of 2 mW was focused to a spot size of ∼5 µm using a 15× Schwarzschild objective (NA = 0.4). The emitted luminescence was collected by the same objective, spectrally analysed using a Fourier-transform infrared spectrometer, and detected using a liquid-nitrogen-cooled InSb detector with cutoff at 0.27 eV. The samples were mounted in a helium cold-finger cryostat. Steep, 900-nm-deep sidewalls and facets of the waveguide were fabricated using an SF6/C4F8-based reactive ion etching process. The gain measurements and lasing demonstration were performed using a pulsed laser (5 ns) emitting at a wavelength of 1,064 nm and focused via a cylindrical lens onto a variable slit imaged 1:1 onto the sample by a biconvex lens.

Cross-sectional TEM specimens were prepared using a dual-beam focused ion beam (FIB) apparatus (FEI Helios Nanolab 400S) operated at 30 and 5 kV. A 3-µm-thick Pt/C protective layer was deposited on the surface of the sample before FIB milling. Surface damage by Ga ions was reduced by low-energy (<1 kV) Ar ion milling using the Fischione Instruments Model 1040 Nanomill system. Conventional and high-resolution images were recorded using an aberration-corrected (fourth-order) FEI Titan 80–300 transmission electron microscope operated at 300 kV.

References

Iyer, S. S. & Xie, Y. H. Light emission from silicon. Science 260, 40–46 (1993).

Rong, H. et al. An all-silicon Raman laser. Nature 433, 292–294 (2005).

Fang, A. W. et al. Electrically pumped hybrid AlGaInAs–silicon evanescent laser. Opt. Express 14, 9203–9210 (2006).

Justice, J. et al. Wafer-scale integration of group III–V lasers on silicon using transfer printing of epitaxial layers. Nature Photon. 6, 612–616 (2012).

Yang, H. et al. Transfer-printed stacked nanomembrane lasers on silicon. Nature Photon. 6, 617–622 (2012).

Liu, H. et al. Long-wavelength InAs/GaAs quantum-dot laser diode monolithically grown on Ge substrate. Nature Photon. 5, 416–419 (2011).

Chen, R. et al. Nanolasers grown on silicon. Nature Photon. 5, 170–175 (2011).

Chen, R. et al. Demonstration of a Ge/GeSn/Ge quantum-well microdisk resonator on silicon: enabling high-quality Ge(Sn) materials for micro- and nanophotonics. Nano Lett. 14, 37–43 (2014).

Sánchez-Pérez, J. R. et al. Direct-bandgap light-emitting germanium in tensilely strained nanomembranes. Proc. Natl Acad. Sci. USA 108, 18893–18898 (2011).

Süess, M. J. et al. Analysis of enhanced light emission from highly strained germanium microbridges. Nature Photon. 7, 466–472 (2013).

Samuel, I. D. W., Namdas, E. B. & Turnbull, G. A. How to recognize lasing. Nature Photon. 3, 546–549 (2009).

Xia, F., Sekaric, L. & Vlasov, Y. Ultracompact optical buffers on a silicon chip. Nature Photon. 1, 65–71 (2007).

Assefa, S., Xia, F. & Vlasov, Y. A. Reinventing germanium avalanche photodetector for nanophotonic on-chip optical interconnects. Nature 464, 80–84 (2010).

Xu, Q., Schmidt, B., Pradhan, S. & Lipson, M. Micrometre-scale silicon electro-optic modulator. Nature 435, 325–327 (2005).

Soref, R. Mid-infrared photonics in silicon and germanium. Nature Photon. 4, 495–497 (2010).

Roelkens, G. et al. Silicon-based photonic integration beyond the telecommunication wavelength range. IEEE J. Sel. Top. Quantum Electron. 20, 394–404 (2014).

Duan, G.-H. et al. Hybrid III–V on silicon lasers for photonic integrated circuits on silicon. IEEE J. Sel. Top. Quantum Electron. 20, 158–170 (2014).

Heck, M. J. R. & Bowers, J. E. Energy efficient and energy proportional optical interconnects for multi-core processors: driving the need for on-chip sources. IEEE J. Sel. Top. Quantum Electron. 20, 1–12 (2014).

Liu, J. et al. Tensile-strained, n-type Ge as a gain medium for monolithic laser integration on Si. Opt. Express 15, 11272–11277 (2007).

Liu, J., Sun, X., Camacho-Aguilera, R., Kimerling, L. C. & Michel, J. Ge-on-Si laser operating at room temperature. Opt. Lett. 35, 679–681 (2010).

Camacho-Aguilera, R. E. et al. An electrically pumped germanium laser. Opt. Express 20, 11316–11320 (2012).

Carroll, L. et al. Direct-gap gain and optical absorption in germanium correlated to the density of photoexcited carriers, doping, and strain. Phys. Rev. Lett. 109, 057402 (2012).

De Kersauson, M. et al. Optical gain in single tensile-strained germanium photonic wire. Opt. Express 19, 17925–17934 (2011).

Sukhdeo, D. S., Nam, D., Kang, J.-H., Brongersma, M. L. & Saraswat, K. C. Direct bandgap germanium-on-silicon inferred from 5.7% 〈100〉 uniaxial tensile strain. Photon. Res. 2, A8 (2014).

Jenkins, D. & Dow, J. Electronic properties of metastable GexSn1–x alloys. Phys. Rev. B 36, 7994–8000 (1987).

Lu Low, K., Yang, Y., Han, G., Fan, W. & Yeo, Y. Electronic band structure and effective mass parameters of Ge1–xSnx alloys. J. Appl. Phys. 112, 103715 (2012).

Gupta, S., Magyari-Köpe, B., Nishi, Y. & Saraswat, K. C. Achieving direct band gap in germanium through integration of Sn alloying and external strain. J. Appl. Phys. 113, 073707 (2013).

He, G. & Atwater, H. A. Interband transitions in SnxGe1–x alloys. Phys. Rev. Lett. 79, 1937–1940 (1997).

Grzybowski, G. et al. Next generation of Ge1–ySny (y = 0.01–0.09) alloys grown on Si(100) via Ge3H8 and SnD4: reaction kinetics and tunable emission. Appl. Phys. Lett. 101, 072105 (2012).

Chen, R. et al. Increased photoluminescence of strain-reduced, high-Sn composition Ge1–xSnx alloys grown by molecular beam epitaxy. Appl. Phys. Lett. 99, 181125 (2011).

Wirths, S. et al. Tensely strained GeSn alloys as optical gain media. Appl. Phys. Lett. 103, 192110 (2013).

Wirths, S. et al. Band engineering and growth of tensile strained Ge/(Si)GeSn heterostructures for tunnel field effect transistors. Appl. Phys. Lett. 102, 192103 (2013).

Gencarelli, F. et al. Crystalline properties and strain relaxation mechanism of CVD grown GeSn. ECS J. Solid State Sci. Technol. 2, P134–P137 (2013).

Gerthsen, D., Biegelsen, D., Ponce, F. A. & Tramontana, J. C. Misfit dislocations in GaAs heteroepitaxy on (001) Si. J. Cryst. Growth 106, 157–165 (1990).

Sun, X., Liu, J., Kimerling, L. C. & Michel, J. Direct gap photoluminescence of n-type tensile-strained Ge-on-Si. Appl. Phys. Lett. 95, 011911 (2009).

Ryu, M.-Y., Harris, T. R., Yeo, Y. K., Beeler, R. T. & Kouvetakis, J. Temperature-dependent photoluminescence of Ge/Si and Ge1–ySny/Si, indicating possible indirect-to-direct bandgap transition at lower Sn content. Appl. Phys. Lett. 102, 171908 (2013).

Geiger, R. et al. Excess carrier lifetimes in Ge layers on Si. Appl. Phys. Lett. 104, 062106 (2014).

Shaklee, K. L., Nahory, R. E. & Leheny, R. F. Optical gain in semiconductors. J. Lumin. 7, 284–309 (1973).

Acknowledgements

The authors acknowledge the hospitality of the IR beamline of the SLS, where the photoluminescence experiments were performed. Part of this work was funded by the Swiss National Science Foundation (SNF). This research received funding for CVD growth investigations from the European Community's Seventh Framework Programme (grant agreement no. 619509; project E2SWITCH) and the BMBF project UltraLowPow (16ES0060 K).

Author information

Authors and Affiliations

Contributions

J.M.H. fabricated the Ge/Si substrates. S.W. and D.B. planned the GeSn epitaxial growth experiments and S.W. and N.v.d.D. fabricated the GeSn/Ge/Si samples. M.L. and S.C. carried out the TEM measurements and analysis. S.W., D.B., G.M., N.v.d.D. and T.S. carried out crystal structure analysis including strain determination via XRD and RBS. Z.I. performed the bandstructure simulations. S.W. and R.G. performed the optical measurements. R.G. and H.S. performed the JDOS modelling, gain analysis and mode simulations. R.G. processed the GeSn cavities. S.M., J.F., D.B., H.S. and D.G. supervised the experiments and coordinated data interpretation. S.W., H.S., R.G. and D.B. wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 1236 kb)

Rights and permissions

About this article

Cite this article

Wirths, S., Geiger, R., von den Driesch, N. et al. Lasing in direct-bandgap GeSn alloy grown on Si. Nature Photon 9, 88–92 (2015). https://doi.org/10.1038/nphoton.2014.321

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nphoton.2014.321

This article is cited by

-

Direct bandgap emission from strain-doped germanium

Nature Communications (2024)

-

Prospects and applications of on-chip lasers

eLight (2023)

-

Vertical GeSn nanowire MOSFETs for CMOS beyond silicon

Communications Engineering (2023)

-

Short-wave infrared cavity resonances in a single GeSn nanowire

Nature Communications (2023)

-

Unlocking the monolithic integration scenario: optical coupling between GaSb diode lasers epitaxially grown on patterned Si substrates and passive SiN waveguides

Light: Science & Applications (2023)